What type of glass is best for my project

How can I tell which type my glass is

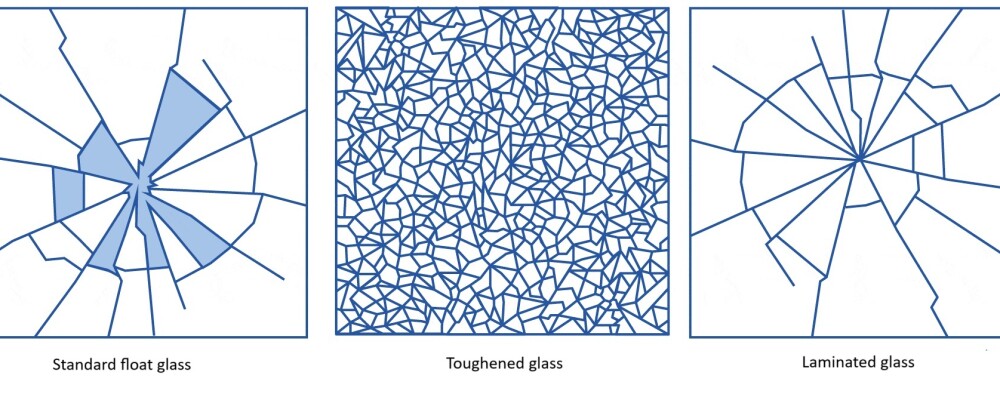

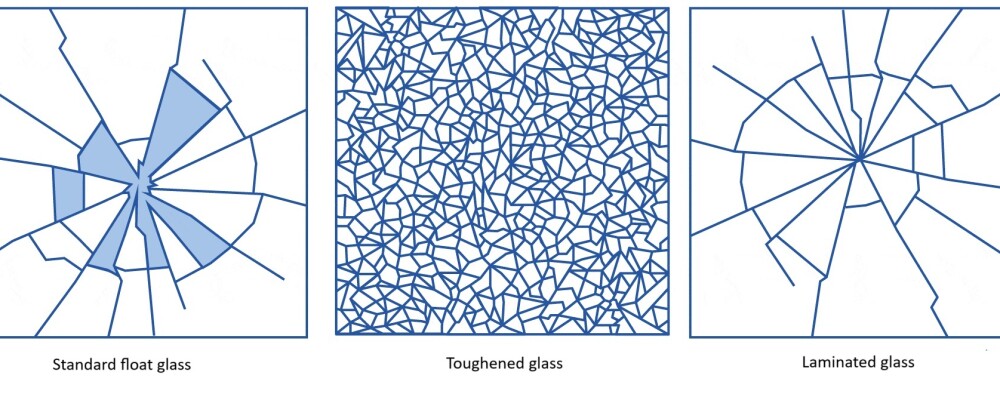

The most definite way to distinguish the three types is by the way they break (see image above)

Toughened glass splinters into a million pieces (car rear windows)

Laminated glass cracks, but does not break (windscreen)

Basic float glass breaks into a number of very sharp pieces (football through window)

Source: https://www.everest.co.uk/glass/glass-types/

Here are some other telltale signs:

Toughened glass: Recognizable most often by a permanent (not erasable) stamp in one of the bottom corners

Laminated glass: Recognizable by a line running through the middle of the panel when viewed edge-on

(if you can see the edge)

Float glass: Less than 1.5sqm size, no stamp, no glue-line on the edge

Where is toughened (tempered) glass used?

Among other things toughened (tempered) glass should be used

where people might accidentally walk into the glass.

on car side panels (for passenger safety during accidents),

on shower screens (to avoid dangerous shards if broken),

in bushfire area windows (where required by Council)for added fire-protection

on balustrades (such as protective barriers on balconies or stairs, to prevent falls),

on glass doors (to reduce injury risk from accidental impact),

on pool surrounds (to help prevent injury from sudden impact), and

on hi-rise façade panels (to reduce risk of injury to pedestrians upon breakage).

How common is toughened glass in buildings and cars ?

Estimates vary but according to Grandview Research the global market size is US $106 billion, which means that 36% of flat glass produced worldwide in 2024 was toughened.

All side and rear glass in cars is toughened. See details in the table below

Where should laminated glass be used?

Anywhere a person might walk into the glass and the glass is framed i.e. in doors or large windows.

In car windscreens, where laminated glass is mandatory due to its ability to stay intact upon impact.

Installations where the panel size exceeds 1.2 square meters (statutory requirements may vary).

Situations where it needs to support a person walking on it, such as glass floors, stair treads, awnings etc

Applications that require a glass thickness of 16mm or more

These scenarios illustrate where laminated glass provides enhanced safety, strength, and compliance with regulations,

Is Laminated Glass Widely Used?

According to Grandview Research, the global laminated glass market is valued at US $76 billion. This represents approximately 26% of all flat glass produced worldwide in 2024. Further details in the table below.

Where can I use float glass?

Float glass is suitable for smaller window panels under 1.2sqm (subject to variations mandated by AS 1288), where cost efficiency is important and there is minimal risk of injury, such as on mirrors and other interior decorative uses.

Is Float Glass Widely Used?

Data from GrandviewResearch indicates that the global market value of basic float glass is approximately US $25.5 billion, accounting for about 9% of all flat glass produced worldwide in 2024, meaning that much of the exterior glass in homes nowadays is either toughened, laminated or double-glazed. Additional details are provided in the table below.

Can all types of glass be polished?

Firstly, toughened glass is the most suitable for polishing. This is because it can withstand high temperatures during the polishing process and does not crack. Up to 15% of the glass’s original thickness can be safely removed during polishing without reducing its strength, which means that even deep scratches or other surface damage can be repaired. From a cost perspective, polishing toughened glass is usually less than half the price of replacing the panel—and sometimes as low as one-tenth of the replacement cost. Around 70% of the glass panels serviced by Glass Restore Australia are made from toughened glass.

Secondly, laminated glass is also quite amenable to polishing, particularly when it is 10.38 mm thick or more. With careful technique—specifically, by ensuring the glass does not overheat—an experienced operator can polish away most surface imperfections without causing the glass to crack. Approximately 20% of the glass panels that Glass Restore repairs are made from laminated glass,

Lastly, float glass can be polished in theory, especially for panels that are at least 6 mm thick. However, because float glass is generally less expensive to produce and replace, it is often more cost-effective to simply install a new panel if the original is scratched or stained. For this reason, less than 10% of the glass panels that Glass Restore Australia repairs are made from basic float glass.

By understanding the properties and repair options for each type of glass, building owners and specifiers can make more informed decisions about glass surface repair and/or replacement.

Are low-e and double glazing typically made using toughened, laminated, or float glass?

Low-e glass, which incorporates a special surface treatment to improve thermal performance, can be toughened or laminated but is rarely applied to standard float glass. In double-glazed window units, the two panels are typically a combination of toughened and laminated glass, chosen according to the project’s safety, security, or acoustic requirements.

Type of Glass | Global market size | Global market share | Glass Restore repair share |

|---|---|---|---|

Toughened | 106.0 | 36% | 55% |

Laminated | 76.0 | 26% | 15% |

Double glazed | 85.5 | 29% | 25% |

Basic float | 25.5 | 9% | <10% |

Total | 292.0 | 100% |

Source: